To overcome the current technical bottlenecks in two-in-one thermal management compressors and drive industry-wide energy efficiency upgrades, on August 6, 2025, a delegation led by General Manager Hou Yidong conducted an in-depth technical inspection and exchange at Compressor and Southern Changsheng Compressor manufacturers. This visit focused on core issues such as high-efficiency energy conservation, thermal management optimization, and system integration. Through on-site observation, technical discussions, and solution workshops, the delegation explored solutions to industry pain points.

The delegation toured Compurui’s compressor production lines, testing center, and product laboratories (as shown in Figure 1), with particular emphasis on examining their high-efficiency heat exchange system: Equipped with adaptive algorithms, the compressors dynamically adjust rotational speed based on load conditions, achieving substantial energy savings compared to conventional models in real-world testing. Modular layout optimizes space utilization, reducing overall unit size for enhanced suitability in space-constrained applications.

Figure 1

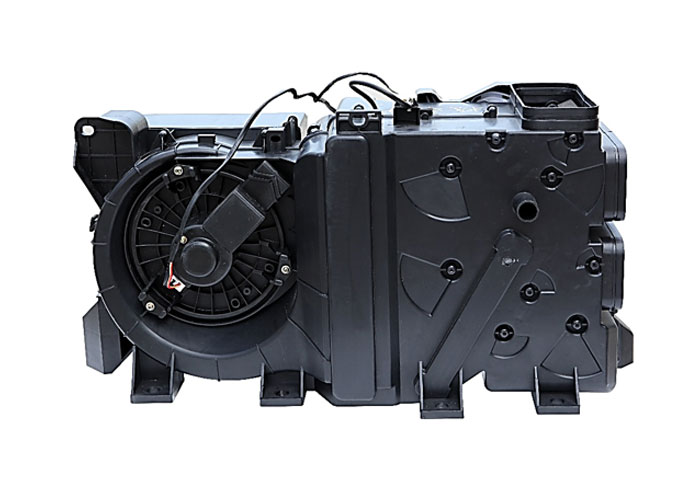

After concluding their in-depth investigation of Compri’s thermal management compressor technology, the delegation promptly moved to Nanfang Changsheng Compressor Factory (as shown in Figure 2), focusing on the differentiated advantages of its high-pressure scroll technology and system integration solutions. Unlike Compri’s positioning on “high efficiency and energy savings,” Nanfang Changsheng excels in high-reliability materials and intelligent diagnostic systems. The complementary nature of their technical approaches offers a more comprehensive solution to overcoming the bottlenecks in “integrated drive-compressor” technology. Both parties engaged in in-depth discussions addressing current challenges in integrated thermal management compressors, including energy efficiency degradation, system integration optimization, and maintenance convenience.

Figure 2

Southern Changsheng showcased its high-pressure scroll compressor and integrated unit solutions: carbon fiber-reinforced scroll discs offer 30% higher pressure resistance and extended service life; built-in vibration sensors enable early warning of bearing wear and other faults; and support for plug-and-play driver integration shortens customer integration cycles. Mr. Hou raised on-site: “Further solutions are needed for seal reliability under high-frequency start-stop cycles.” Southern Prosperity responded that it would collaborate with material suppliers on targeted improvements. Both teams held closed-door discussions on common industry challenges, reaching the following consensus: jointly develop shielding coatings to reduce driver interference with compressor sensors; establish joint test benches to validate comprehensive energy efficiency under varying loads; and promote industry-standard interface protocols to reduce customization costs.

Following the completion of the compressor technology assessment at Purison and Southern Changsheng, the delegation proceeded to the third stop—the Liyang Thermal Management Laboratory (Figure 3). As a key research platform in the Yangtze River Delta region, it primarily conducts core experiments and research focused on three major areas: thermodynamics, materials science, and system integration. This facility serves not only as the validation endpoint for thermal management technologies but also as the starting point for system integration. Its unique end-to-end testing capabilities—spanning materials, components, and complete units (e.g., thermal resistance testing of graphene gaskets, microchannel flow observation)—provide the basis for synergistic optimization of the compressor and drive prototypes observed earlier.

Figure 3

From the precision workshops of Compure and Nanfang Changsheng to the intelligent thermal simulation platform at the Liyang laboratory, this inspection tour served not only as a “diagnostic journey” for tackling technical challenges but also as a “foundational expedition” for building the industrial ecosystem. We have gained profound insight: Only by seamlessly integrating engineering expertise from enterprises, validation capabilities from laboratories, and scenario-based demands from the market can we truly overcome critical bottlenecks. Moving forward, Xinrun Intelligence will collaborate with partners, using this inspection as a starting point, to advance the implementation of efficient, stable, and intelligent thermal management compressor technology, thereby driving green industry upgrades.