As the global construction machinery industry undergoes an electrification revolution, a seemingly peripheral technical component – battery thermal management – has emerged as a critical bottleneck. When electric loaders and excavators frequently experience power limitations, shutdowns, or even battery damage in extreme environments, the industry must confront this formidable challenge head-on.

Thermal Management: The “Achilles’ Heel” of Electric Construction Machinery

Traditional electrification approaches borrowed thermal management solutions from passenger or commercial vehicles, neglecting construction machinery’s unique demands:

- Extreme operating conditions: Equipment like excavators and loaders operate continuously under high loads in environments ranging from -30°C Arctic mines to 50°C desert construction sites;

- Space constraints: Compact layouts limit radiator size, causing precipitous performance declines during summer heatwaves and triggering controller alarms or motor derating;

- Energy consumption paradox: Traditional electric heating solutions in cold environments drain battery capacity, drastically reducing operational endurance.

According to XCMG’s field tests, at -25°C, unoptimized battery packs suffer 40% reduced discharge capacity with 200% longer charging times. These pain points directly undermine customer confidence in electric equipment reliability.

How Chinese Innovators Are Breaking Through

Path 1: Multi-dimensional Data Fusion for Precision Control

Xuzhou Xinrun Intelligence’s 2024 launch of its multi-dimensional data-based intelligent battery thermal supervision system represents a new paradigm in data-driven thermal management. This system coordinates three core modules:

- Data analysis module: Extracts non-thermal parameters (voltage, current, internal resistance) to construct multi-dimensional feature combinations and generate dynamic fitting functions predicting “analytical temperature”;

- Anomaly diagnostics: Calculates deviation values(|Analytical Temp – Monitored Temp| / Analytical Temp) to generate deviation curves for early fault detection;

- Spatial optimization algorithm: Patented coordinate merging technology boosts processing efficiency by intelligently consolidating adjacent points based on distance and temperature differentials.

This approach increases temperature monitoring accuracy by 30% and reduces anomaly response time to under 2 seconds – shifting from “post-failure alarms” to “pre-failure prevention.”

Path 2: Integrated Thermal Ecosystem Design

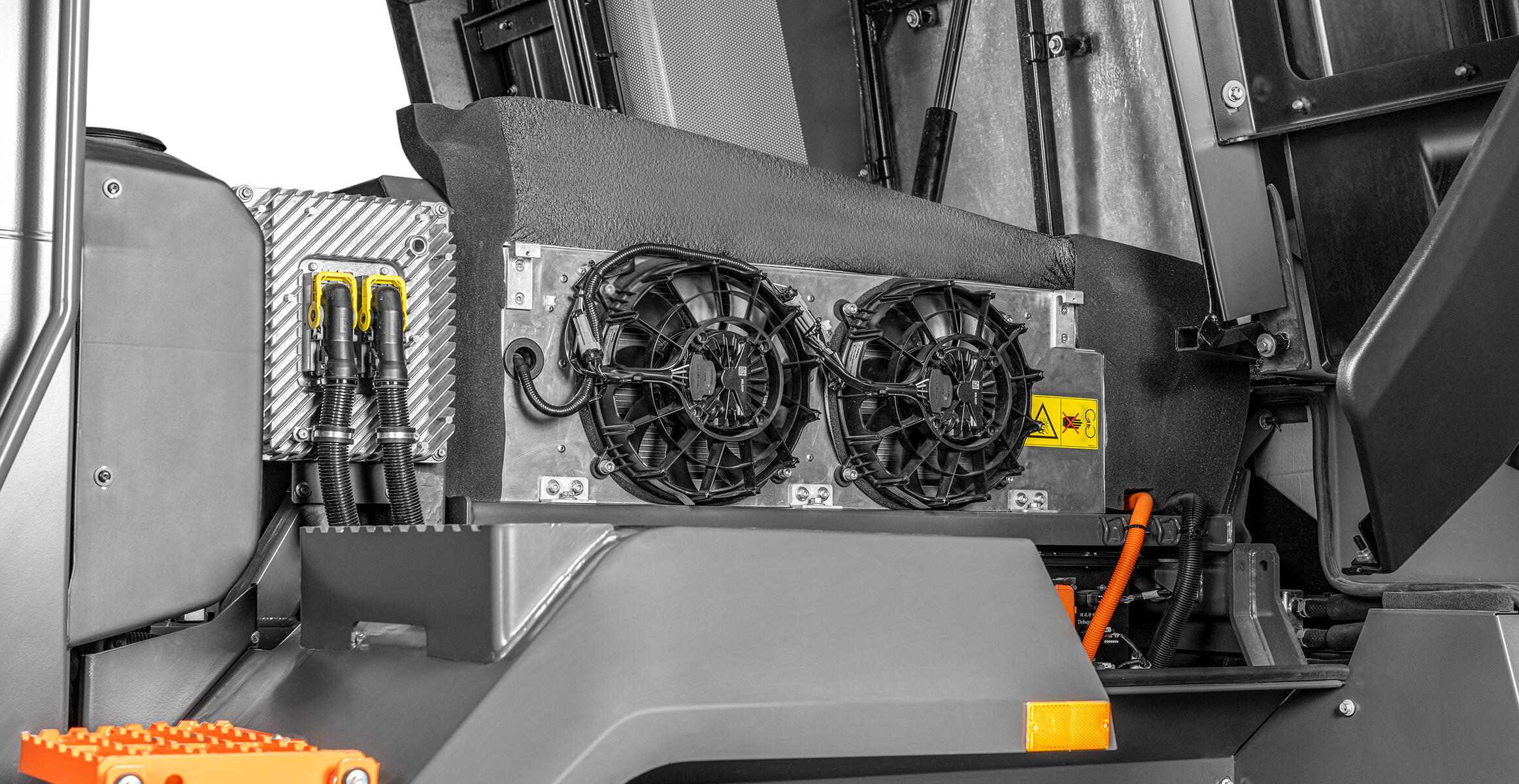

XCMG Research Institute’s multi-subsystem coupling technology dismantles traditional fragmented architectures:

- Shared radiatorsbetween air conditioning and motor cooling circuits eliminate redundant components;

- Hydraulic waste heat recovery: Transfers heat from hydraulic systems to batteries during cold starts, while heating hydraulic oil via dedicated heat exchange loops;

- Dynamic routing control: An electromagnetic valve network (e.g., 1st/2nd/3rd solenoid valves) enables real-time coolant path switching between series and parallel modes.

This integrated approach reduces components by 25% and cuts energy consumption by 40% in cold environments – eliminating the “bigger radiator” arms race.

Path 3: Scenario-Intelligent Strategies

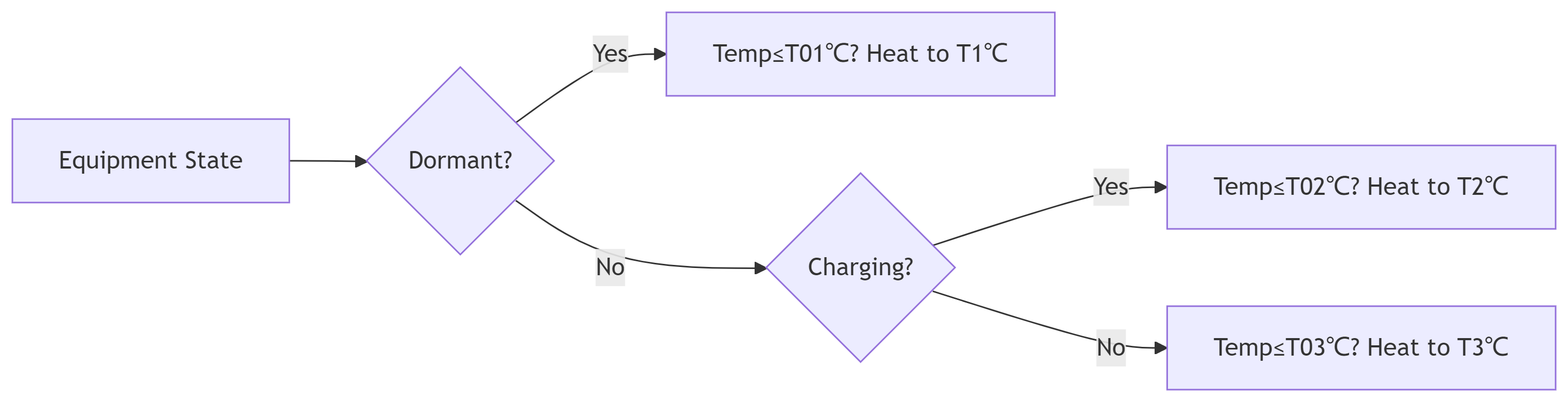

XCMG’s 2024 patent for electric loader battery thermal management demonstrates deep adaptation to operational scenarios:

The system sets distinct temperature thresholds (T01/T02/T03) and heating targets (T1/T2/T3) for dormant, charging, and working states, achieving granular energy allocation. Field tests in Northeast China mines reduced cold-weather battery failures by 90%.

The Underlying Logic of Technological Breakthroughs

Chinese innovators’ thermal management revolution represents a paradigm shift from “single-point monitoring” to “system-level optimization”:

- Material innovations:Graphene thermal films and phase change materials (PCMs) buffer cells against thermal shock;

- Control system evolution:Reinforcement learning-based dynamic parameter adjustment replaces fixed temperature thresholds;

- Energy rebalancing: Xinrun’s coordinate consolidation algorithm reduces processor load by 15% through eliminating redundant data points.

The Chinese Solution in Global Competition

While Western manufacturers pursue larger radiators and more powerful cooling systems, Chinese companies chart a new course with “data-driven intelligence + systemic integration”: Xinrun’s predictive analytics and XCMG’s thermal networks outline a distinct approach – solving complexity through algorithms and architecture, not brute force.

With XCMG’s latest dual-sided cooling battery module patent (CN119253127A) – featuring independent cooling circuits on parallel cell surfaces that improve temperature uniformity by 50% – Chinese solutions are now contributing to global standards.

Conclusion: Thermal Management as the New Core Competency

Battery thermal management’s evolution from “auxiliary system” to “mission-critical hub” signals construction machinery electrification’s maturation. Innovators like Xuzhou Xinrun Intelligence prove that breaking bottlenecks requires rewriting rules, not incremental patches. When thermal systems transform from energy drains into efficiency engines, China’s electric construction machinery revolution will truly surge forward.